How to Troubleshoot an Overflow Valve Block Issue?

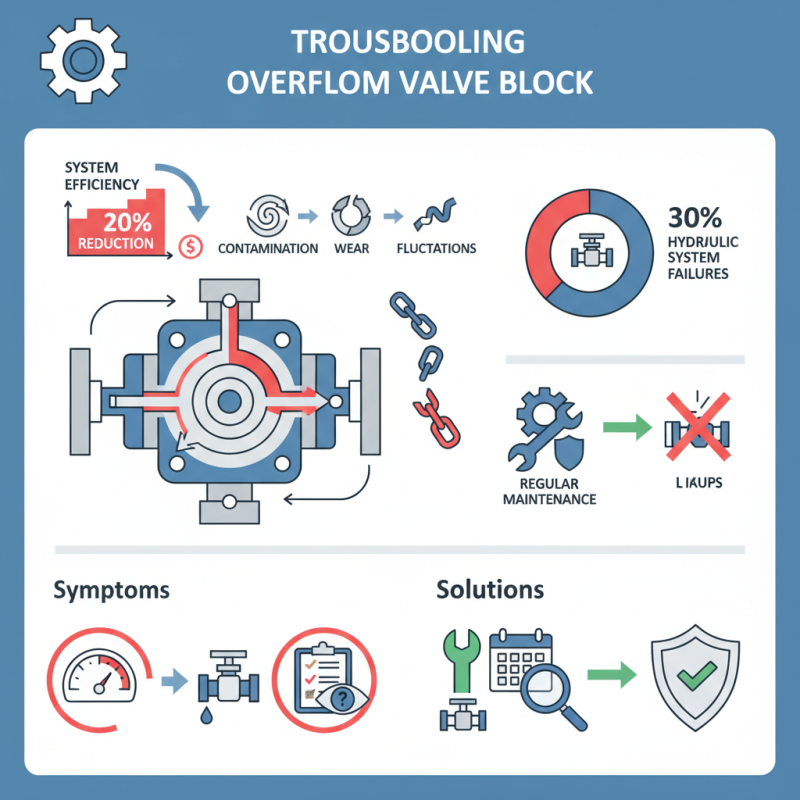

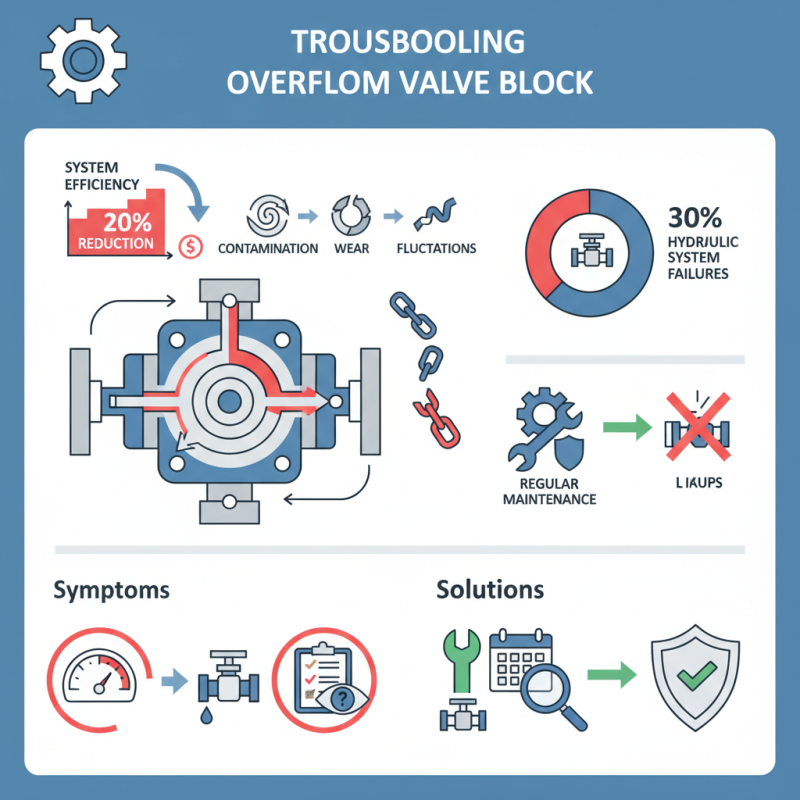

Troubleshooting an Overflow Valve Block issue is crucial for maintaining fluid control systems. An overflow valve block plays a vital role in hydraulic applications. According to industry reports, inefficient valve performance can lead to approximately 20% reduction in system efficiency. This inefficiency often results in increased operational costs and potential equipment damage.

Understanding why these blockages occur is essential. Factors like contamination, wear, and pressure fluctuations contribute to overflow valve block issues. Recent data shows that nearly 30% of hydraulic system failures are linked to malfunctioning valves. Regular maintenance can prevent severe problems, yet many neglect this critical aspect.

Common symptoms of an overflow valve block issue include abnormal pressure readings and unexpected fluid leaks. Addressing these signs early can save significant time and resources. It is important to reflect on maintenance routines and consider potential oversights. Neglecting these small issues can lead to larger, more expensive repairs down the line.

Identify Symptoms of Overflow Valve Block Issues

When dealing with overflow valve block issues, identifying symptoms is crucial. Common signs include unusual noises during operation. You might also notice frequent system pressure readings that are inconsistent. These irregularities can indicate that something is wrong with the valve.

Another symptom to watch for is fluid leaks. If you see any visible leakage around the valve, this could point to blockages. Additionally, check if the system is experiencing overheating. High temperatures might suggest restricted fluid flow due to the block. These indications shouldn't be ignored, as they can lead to further complications.

Keep an eye on the system's responsiveness. If it operates slower than usual, something could be blocking the valve. Try to observe these symptoms closely. Noticing them early can help in troubleshooting effectively. Remember, no system is perfect, and recognizing flaws is part of the process.

How to Troubleshoot an Overflow Valve Block Issue? - Identify Symptoms of Overflow Valve Block Issues

| Symptom | Possible Cause | Recommended Action |

| Inconsistent Pressure | Clogged or damaged valve | Inspect and clean or replace the valve |

| Fluid Leakage | Worn seals or fittings | Check seals and fittings for wear; replace if necessary |

| Overheating | Blocked fluid flow | Clear blockages in the system |

| Erratic Operation | Faulty control mechanism | Test the control mechanism; repair or replace if faulty |

| Increased Wear on Components | Improper pressure settings | Reassess and adjust pressure settings |

Examine the Overflow Valve and Its Components

Examining the overflow valve and its components is crucial in troubleshooting related issues. Begin by visually inspecting the valve for any visible signs of wear or damage. Look for cracks, leaks, or corrosion on both the valve body and connections. These can lead to malfunction and reduced efficiency. It’s also essential to check the seating surfaces. They should be clean and free of debris. Dirty or damaged seats can cause improper sealing, resulting in reduced performance.

Next, focus on the internal components of the valve. Take note of the spring and diaphragm. The spring should not be corroded or weakened. A weak spring can fail to create the necessary pressure. Similarly, inspect the diaphragm for any tears or punctures. Even minor issues here can lead to significant failures.

While analyzing these components, remember that a thorough check often reveals underlying problems. Sometimes, issues are subtle and need careful attention. Regular inspection may highlight wear that often goes unnoticed. If you encounter persistent problems, consider evaluating the entire system. Connections and other related components might contribute to the overflow issue. Always approach these inspections methodically to ensure accuracy.

Check for Obstructions in the Hydraulic System

When troubleshooting an overflow valve block issue, checking for obstructions in the hydraulic system is essential. Many problems stem from debris or blockages that disrupt fluid flow. Start by examining hoses and connections for any signs of wear or damage. A small kink can lead to significant issues.

Inspect filters regularly. Dirty filters can restrict flow and cause pressure build-up. Clearing them can resolve many hidden problems. It's also beneficial to check fittings and seals. A tiny leak might not seem serious, but it can lead to bigger complications down the line.

Remember, even minor obstructions can cause major headaches. Don't overlook small issues. The hydraulic system can be unforgiving. Always keep an eye out for unusual sounds or changes in performance. Documenting these changes might provide insights for future maintenance. A proactive approach can prevent a full system failure.

Test Pressure and Flow Rates for Proper Functionality

When troubleshooting an overflow valve block issue, test pressure and flow rates are crucial. An ideal overflow valve should maintain a consistent pressure, typically set between 50 to 150 psi for most applications. A malfunctioning valve might cause erratic flow rates, significantly affecting system performance. Research from industry reports shows that discrepancies in flow rates can lead to inefficiencies, sometimes exceeding 20% of total output.

Tip: Regularly monitor the pressure gauge. Look for fluctuations which can indicate blockages or faulty components. To ensure accurate readings, use calibrated equipment. If flow rates drop below 60% of the expected values, investigate further.

Inspecting flow rates involves checking system components. A pressure drop across the valve can signify a restriction. Industry standards recommend performing these checks every 1,000 operating hours. Maintenance records should reflect these updates for proper tracking.

Tip: Don't ignore unusual sounds from the valve. These can often be an early warning sign of a blockage or wear. Always keep an eye on wear indicators and maintain a routine inspection schedule to prevent larger issues down the line.

Perform Necessary Repairs or Replacements of Faulty Parts

Troubleshooting an overflow valve block issue often necessitates hands-on repair work. Identifying faulty components is crucial. According to a report from the Fluid Power Journal, 30% of hydraulic system failures stem from worn-out parts. Regular inspections can prevent unexpected shutdowns. A blocked overflow valve can lead to catastrophic failures. Therefore, timely repairs are essential.

When parts are deemed faulty, replacement is the next step. It's not uncommon for operators to overlook small wear or leaks. These minor issues escalate into larger problems. The International Society for Fluid Power estimates that 20% of hydraulic failures result from ignored minor issues. Always check seals and springs; they often fail first. Avoiding such checks can lead to expensive repair bills.

Remember, conducting repairs isn't solely about part replacement. It involves understanding the system's dynamics. Each part plays a role in overall function. If you replace without evaluation, the same issues may recur. Emphasize thorough inspections alongside repairs for long-term reliability. Engage with technicians to analyze component performance. Their insights can guide better maintenance strategies.