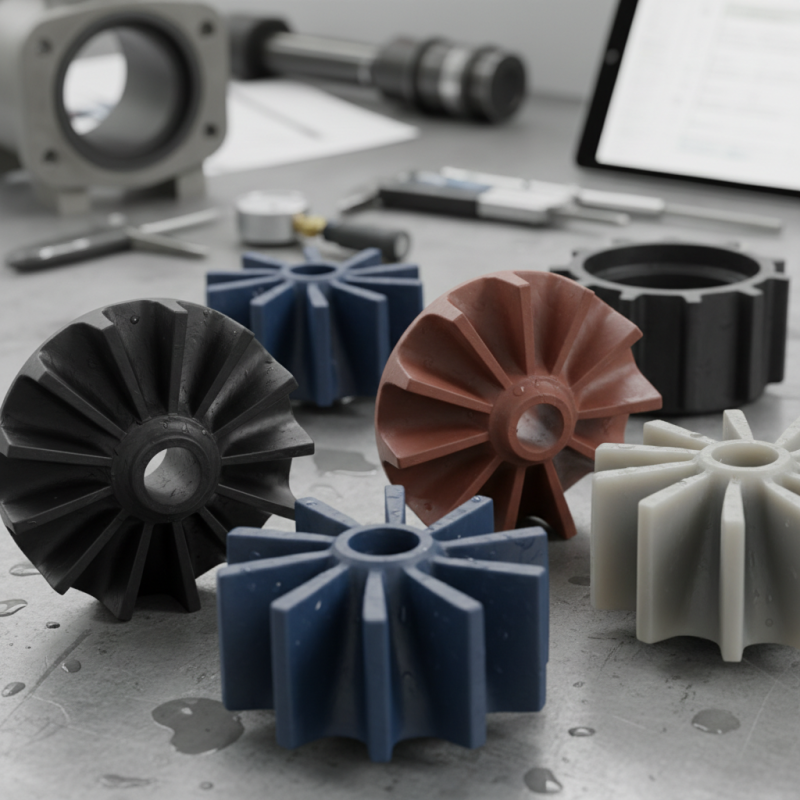

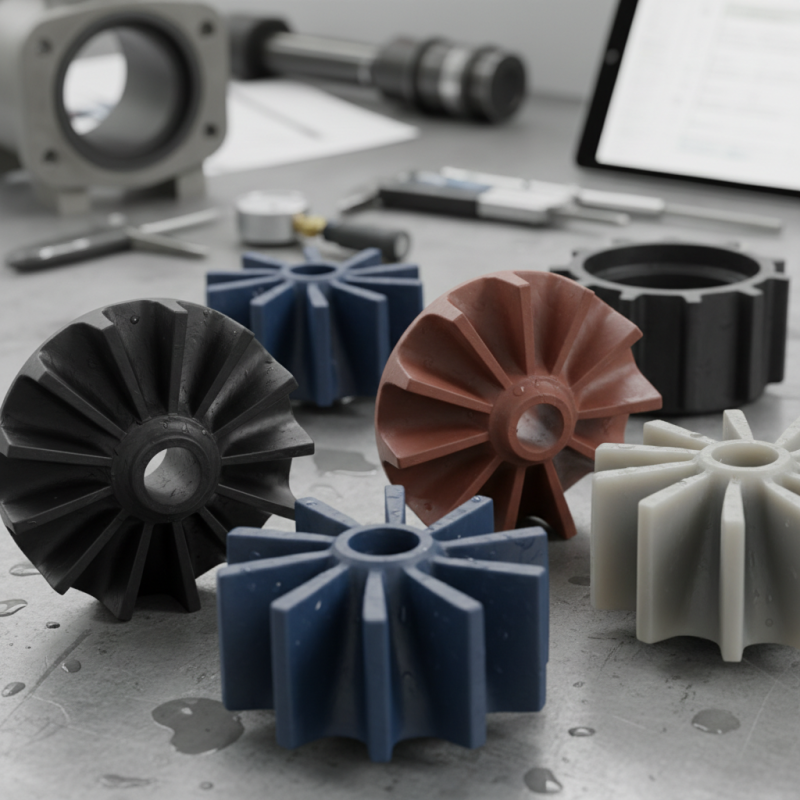

How to Choose the Right Rubber Pump Impeller for Your Needs?

Choosing the right Rubber Pump Impeller is crucial for efficiency in various applications. The impeller significantly impacts the performance of your pump, influencing flow rates and pressure. Not all impellers are created equal. You need to consider specific factors based on your unique requirements.

Different materials and designs can affect durability and resistance to wear. A Rubber Pump Impeller can offer flexibility and is often more resistant to harsh chemicals. However, it's essential to ensure that the rubber formulation suits your environment. Missteps in selection may lead to reduced efficiency or frequent replacements, which can be costly.

In many cases, users overlook the importance of proper sizing. An impeller that is too large or too small can lead to performance issues. Reflecting on your application’s needs can guide your choice more effectively. Don’t underestimate the impact of each component. A small oversight may lead to significant setbacks.

Understanding the Functionality of Rubber Pump Impellers

Rubber pump impellers play a critical role in various pumping applications. They are designed to transfer fluid efficiently and effectively. According to industry reports, around 70% of pump failures are attributed to pump wear, often linked to impeller material. Rubber impellers are known for their durability and flexibility, making them suitable for handling abrasive materials. This is essential in sectors like wastewater treatment and chemical processing, where fluid composition can vary widely.

In selecting the right rubber impeller, consider the application environment. High-chemical resistance is crucial for corrosive fluids. An improper fit can lead to leaks and inefficiencies. Studies indicate that using the correct impeller can enhance pump efficiency by up to 30%. However, not every rubber type will suit your needs.

Impeller design, including diameter and blade shape, impacts performance significantly.

Regular maintenance is often overlooked but is vital to sustaining performance. A worn impeller can reduce flow rates and increase energy costs. Additionally, you should monitor for signs of wear and degradation. Ignoring these signs can lead to costly downtimes. Remember, the right rubber pump impeller can make a difference in overall operational efficiency. However, the decision process often requires careful consideration of various factors.

Factors to Consider When Selecting a Rubber Pump Impeller

Choosing the right rubber pump impeller is essential for performance. Several factors impact your decision. Know the fluid you will pump. Different fluids can affect impeller material and design.

Consider the temperature range. High temperatures can degrade some rubber types. Look for impellers that withstand specific temperatures. Check the pH level of your fluid. Compatibility is crucial for long-lasting performance.

Tips: Always test the impeller in a sample environment. This helps you identify any potential issues. Take note if the impeller shows wear sooner than expected. Reflect on its performance and decide if adjustments are needed.

Don’t overlook the size and capacity. The size must match your pump dimensions. An ill-fitting impeller can lead to inefficiency. It’s easy to dismiss this detail, but the right fit promotes better flow and pressure.

Types of Rubber Pump Impellers and Their Applications

Rubber pump impellers come in various types, each suited for specific tasks. For example, open impellers are easy to clean. They work well with fluids containing solids. This makes them a popular choice in wastewater treatment. However, they may not be the best option for high-pressure applications.

Closed impellers, on the other hand, provide higher efficiency. They handle viscous fluids better. They are often used in environments requiring precision. But, their design can make them difficult to clean. This might become an issue if the fluid has impurities. A reflection on cleaning processes is essential here.

Vortex impellers are another type worth noting. They create a whirlpool effect to handle slurries. Their unique design prevents clogs, but they might lower the efficiency in some cases. Evaluating the trade-offs of each impeller type ensures you choose wisely. It’s not an easy decision, and each application may demand a different approach. Understanding these factors can lead to more effective pumping solutions.

Evaluating Material Compatibility for Rubber Impellers

When selecting a rubber pump impeller, material compatibility is crucial. Different operating environments require different materials. For example, a study from the Rubber Manufacturers Association (RMA) indicates that EPDM rubber is ideal for applications involving water and steam. However, it may not stand up well to oil-based products. This mismatch can lead to premature wear and failure.

Temperature resistance is another key factor in material selection. According to the American Society for Testing and Materials (ASTM), some rubber compounds perform poorly over time when exposed to extreme temperatures. A typical rubber impeller might degrade rapidly in high-heat situations, causing leaks or inefficient pumping. Although many options exist, not every choice is suitable for specific scenarios.

It's worth noting that the compatibility between the impeller and the fluid being pumped is often overlooked. For instance, using a natural rubber impeller in a solvent-heavy environment may lead to swelling and reduced performance. This compromises efficiency and increases maintenance costs, which many operators may not initially consider. Reflecting on material choices can save significant time and resources.

How to Choose the Right Rubber Pump Impeller for Your Needs? - Evaluating Material Compatibility for Rubber Impellers

| Impeller Type | Material Compatibility | Operating Temperature (°C) | Application Area | Corrosive Resistance |

| Open Impeller | Nitrile Rubber (NBR) | -10 to 80 | Water & Wastewater | Moderate |

| Closed Impeller | EPDM | -30 to 120 | Chemical Processing | High |

| Semi-Open Impeller | Natural Rubber (NR) | -10 to 70 | Agricultural Irrigation | Low |

| Vortex Impeller | Silicone | -50 to 200 | Food & Beverage | Excellent |

| Screw Impeller | Hypalon | -20 to 95 | Industrial Waste | Very High |

Maintenance Tips for Longevity of Rubber Pump Impellers

Proper maintenance of rubber pump impellers is crucial for their longevity. Regular inspection can prevent wear. Check for cracks, tears, or other visible damage. Even small issues can escalate quickly. If left unattended, they may lead to major failures.

Cleaning the impeller is essential. Remove any debris or buildup that could affect performance. Use a soft brush and mild detergent. Harsh chemicals may damage the rubber. After cleaning, dry it thoroughly. Moisture can lead to mold growth, which is harmful.

Lubrication is another key aspect. Using the right lubricant can reduce friction. This prolongs the life of the impeller. However, too much lubricant can be counterproductive. It is a delicate balance. Always consult guidelines for the right amount.

Regular maintenance not only extends the impeller's life but also enhances overall pump efficiency.